Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Installation method of glass curtain wall and selection of glass sucker truck

Speaking of the glass curtain wall, the curtain wall on the high-rise building that is bright enough to be used as a mirror should impress everyone most. As a kind of curtain wall, glass curtain wall is not only more beautiful in appearance than other curtain walls, but also more practical. As something we can see everyday, glass curtain walls appear in high-rise buildings. How did he install it? What professional mechanical equipment are required during installation? The following describes the installation method of glass curtain wall and the selection of installation equipment.

Installation method of glass curtain wall - construction scheme of glass curtain wall

1. Collect and prepare relevant materials and tools

Before construction, relevant data shall be collected at the construction site. As the civil construction may have some changes, the actual size may not always be consistent with the design drawings. All glass curtain walls have high requirements for the relevant dimensions of civil structures. So before the design, we must go to the site to measure and obtain the first-hand data, and then draw a feasible curtain wall zoning map according to the requirements of the owner. For the part with the entrance and exit of the gate, it is also necessary to cooperate with the unit making the automatic revolving door and the full glass door to ensure the reliable closing of the glass curtain wall on the door and beside the door, and also to meet the installation and maintenance requirements of the automatic revolving door. The tools to be used should also be prepared in advance.

2. Determination of design and construction scheme

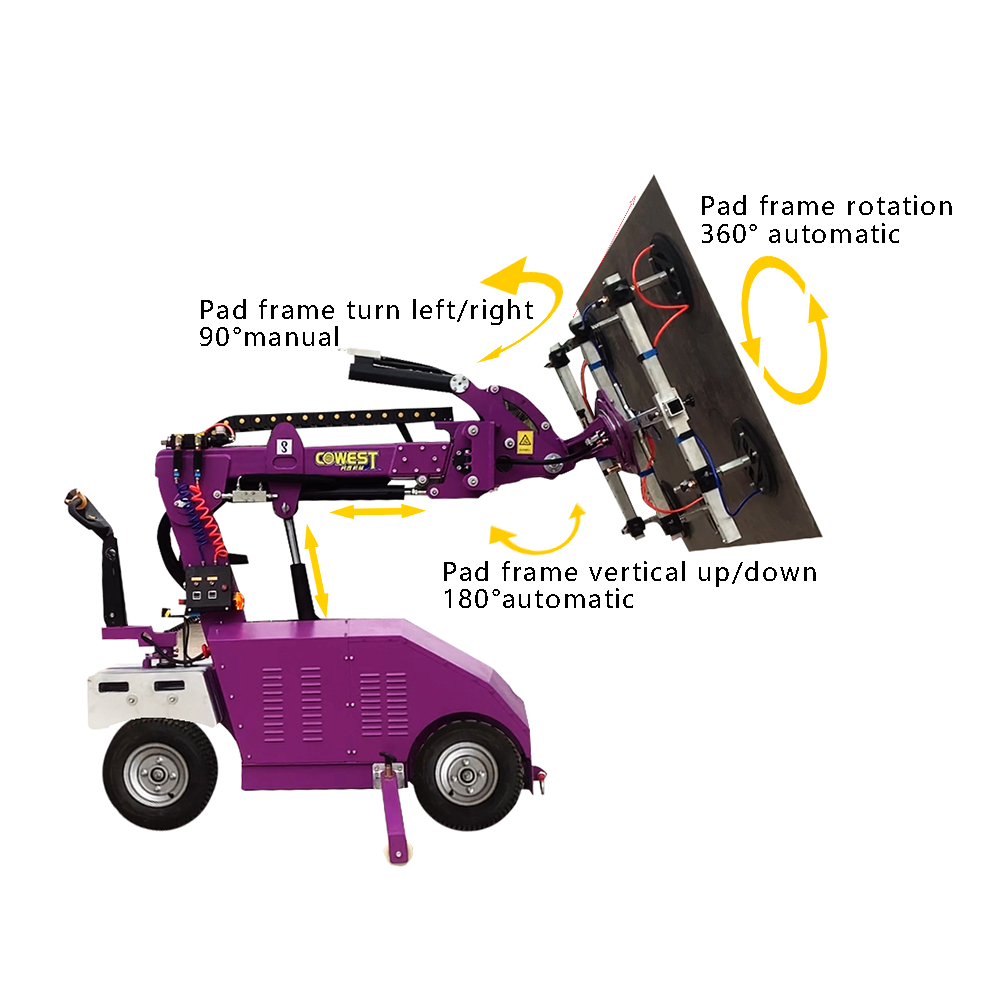

When designing the partition of glass curtain wall, in addition to the uniform and beautiful appearance, attention should also be paid to reducing the size and model of glass as much as possible. Because the outdoor design of various buildings is different, for the projects with large outdoor awnings and driving ramps, more attention should be paid to coordinating the overall construction sequence and progress, so as to prevent the construction of other outdoor facilities from affecting the walking of glass suction cups and the installation of glass curtain walls. Before the formal construction, the site within the construction scope shall be leveled and filled, and the site shall be cleaned to ensure the smooth running of the glass sucker truck.

1. Curtain wall installation

1) Use (laser) theodolite, level, plumb bob and other instruments and tools to measure the central position of the connection point between the frame material and the main structure layer by layer on the main structure. The allowable deviation of the positions in the X, Y and Z directions is 1.0mm

2) For element curtain walls, such as tempered glass, insulating glass and other glass that cannot be cut on site, the actual size of the glass should be checked in advance. If it is inconsistent with the design size, the central position of the connection point between the frame material and the main structure shall be adjusted. Or the glass can be customized according to the actual installation position (size) of the frame material.

3) Fix the connector according to the central position of the measured connection point to ensure its firmness.

4) The unit curtain wall shall be installed from bottom to top. Element curtain wall partition materials shall be installed from top to bottom.

5) When the frame material of the unit curtain wall or each unit of the unit curtain wall is connected with the connector, the whole curtain wall shall be inspected and corrected, and then the connector shall be welded with the embedded parts of the main structure (including anchoring with expansion bolts).

6) The gap of the unit curtain wall shall be sealed with V-shaped, W-shaped or other adhesive strips, and shall be filled without omission.

7) The unit curtain wall glass shall be installed according to the requirements of the design drawings. After the glass is installed in place with the glass sucker truck, it shall be fixed with rubber strips and other filling materials with the frame in time, and shall not be temporarily fixed or suspended.

2. Installation process of unit curtain wall

The on-site installation process of the unit curtain wall is as follows:

Surveying and setting out → checking the position of embedded T-slot → threading screws → fixing the bracket → accurately aligning the bracket → welding the bracket → rough hanging of V-type and W-type adhesive tapes → installing the curtain wall in place with the shock absorption rubber pad → fastening screws → adjusting the straightness of the curtain wall → filling the hot-pressed wind belt → installing the indoor window sill plate and the inner corner brace plate → filling the fireproof and thermal insulation materials between the beams and columns.

3. Installation process of component curtain wall

1) Installation process of exposed frame glass curtain wall

Inspection and classification of curtain wall components → measurement and setting out → assembly of primary and secondary keels → installation of floor fasteners → installation of main keels (strips) and leveling adjustment → installation of secondary keels (strips) → Install insulating galvanized steel plate → weld rivet screws on galvanized steel plate → install interlayer protective mineral wool → install floor sealed galvanized steel plate → install single-layer glass sealing strip and clamp → install single-layer glass on glass suction cart → install double-layer insulating glass sealing strip and clamp → transport and install glass suction cart.

2) Installation process of concealed frame glass curtain wall

Surveying and setting out → installation of fixed support → installation of columns and cross bars → installation of outer enclosure structural members → sealing and sealing treatment of outer enclosure structural members → treatment of fireproof interlayer → cleaning, etc.

4. Installation process of frameless glass

Because the glass or curtain wall unit is long, large and heavy, the current industry construction generally uses the Cowest mechanical special glass sucker truck for construction. The electric glass sucker truck is used to absorb the glass in place. The operator stands on the scaffold set up on both sides of the upper end of the glass, uses the clamping device to fix the upper end of the glass, and each piece of glass is filled with silica gel.

Smart Glass

Installation Robot,Glass

Installation Equipment,Glass

Installation Robot,glass installation lifter,glass installation, Glass

Installation Vacuum Lifter,Glass Lifter Robot,smart glass installation,easily

glass installation, easily glass installation equipment

Envoyer à ce fournisseur

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.